Posted on :- 16-02-2024

Posted on :- 16-02-2024

Korean researchers develop heat-resistant material that withstands 1000°C

Not just high temperatures, the material also works well under extreme UV exposure making it ideal for applications in space too.

A research team at the Korea Institute of Science and Technology (KIST) has developed a thermally refractory material that maintains its optical properties even at temperatures of 1,000 degrees Celsius and in strong ultraviolet illumination. The material can be used in various applications ranging from space and aerospace to thermal photovoltaic (TPV) systems.

Thermal radiation is the term used to define the electromagnetic radiation emitted from all matter whose temperature is above absolute zero. The radiation results from the heat generated when charges in the material move and are released in the form of electromagnetic radiation.

Scientists have been working on tapping this radiation as a form of energy source. The heat from facilities such as thermal power generation plants and industrial sites can be repurposed for heating, cooling, and even energy production when suitable thermal refractory materials are available.

Much of this research has focused on deploying the technology in general environmental conditions. To expand the scope of its application, newer materials are sought with that can operate in extreme environments.

Generating electricity from the Sun

In our attempts to phase out fossil fuels, large-scale energy generation projects using sunlight are underway in various parts of the world. However, the solar radiation spectrum that enters the Earth but remains unutilized is another renewable resource that scientists want to tap into.

“As an alternative to solar and wind renewable energy, whose electricity production varies depending on the weather, eco-friendly thermoelectric power generation technology that uses radiant energy emitted by the Sun and high-temperature environments to generate electricity is gaining attention,” said Jongbum Kim, senior researcher at KIST under whose leadership the team developed the new thermal refractory material.

How was the new material made?

Conventionally, materials like tungsten, nickel, and titanium nitride have been used as refractory conducting materials. However, these materials are easily oxidized at higher temperatures.

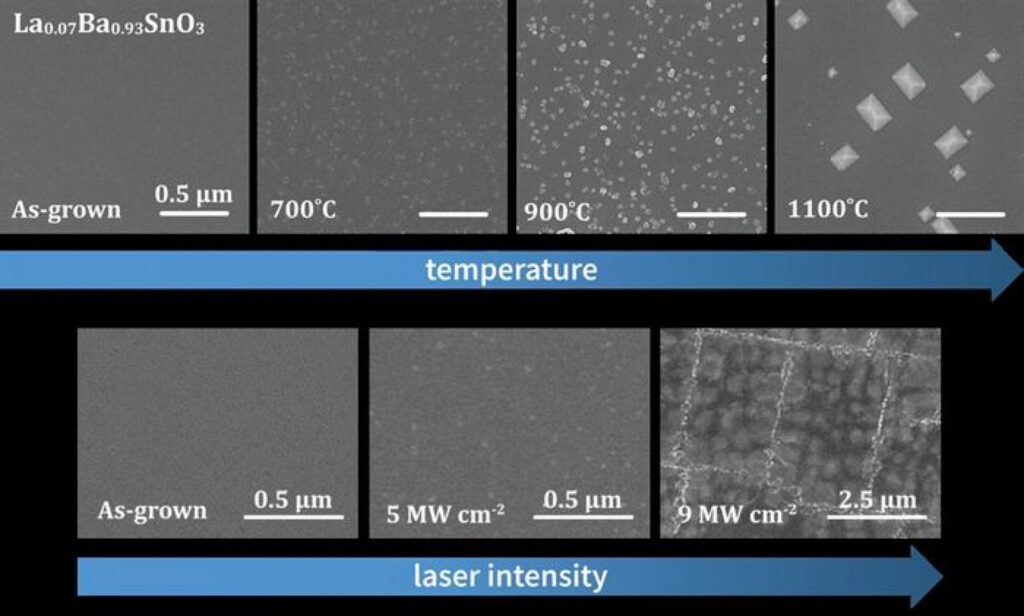

According to the press release, the researchers used pulsed laser deposition techniques to fabricate lanthanum-doped barium stannate oxide (LBSO) in nanoscale thin film. The material can maintain its performance even when exposed to temperatures of 1,000 degrees Celsius and intense ultraviolet light of 9 MW/cm2.

The research team also fabricated a thermal emitter in the infrared band using LBSO and found the material stable when used in multilayers or as a thin film. This opens the possibility of using LBSO for thermophotovoltaic (TPV) power generation. Interestingly, the material allows thermal radiation to be transferred to PV cells without an intermediary, thereby preventing its oxidation from coming in contact with air.

“LBSO will contribute to addressing to climate change and the energy crisis by accelerating the commercialization of thermoelectric power generation,” added Kim in the press release.

The researchers are confident that LBSO will find applications beyond the power generation and recycling of waste heat from industrial equipment. Since it is resistant to UV exposure, the material can also manage heat generated by absorption or exposure to strong sunlight. This typically occurs in extreme environments and can help develop applications in areas of aviation and space.